Dewatering is the process of removing or draining groundwater or surface water from a construction site or a riverbed, mineshaft or caisson by pumping. Dewatering pumps in Zambia are majorly used for water removal or expulsion process in underground mines. In other places dewatering pumps are also used in other industries such as flood dewatering, power plants, cement plants, thermal plants, and construction industries. These dewatering pumps are installed at lower ground levels in construction sites for maintaining and controlling ground water levels. These dewatering pump in Zambia dissipate the need of cost of solids handling.

Factors that affect the lifespan of submersible pump

Listed below are the factors to take into consideration for choosing a dewatering pump with a longer lifespan.

- Construction Material

The materials from which the submersible dewatering pumps also the lifespan of the pump greatly. They are typically of cast iron, stainless steel and thermoplastics. Every material has its own advantage and disadvantage. Pumps made from cast iron are usually less expensive in comparison to pumps made from stainless steel. But they are also more prone to corrosion as well. On the other hand pumps of stainless steel are more expansive then pumps of cast iron but they are more durable and corrosion-resistant. Whereas pumps made from thermoplastics are corrosion-resistant but are not appropriate for heavy-duty applications. - Operating Temperature

Every manufacturer of Submersible dewatering pumps is well aware of the fact that operating temperature of the pumps impacts its service life. The seals and bearings of pump can fail if it’s used in applications with too high or too low temperature. Thus it is of great importance that you use the pump rated to operate in the required temperature range for the specific application. - Power Supply

Power Supply also plays an important role in determining the lifespan of the submersible dewatering pump in Zambia and everywhere else. The impeller along with other components of pump can suffer from premature wear if the supplied voltage is too low. It will slow down the pump. On the contrary too high voltage can overheat the pump causing premature failure as a result. It is important that the pump receives voltage in the recommended range. - Maintenance

This is essential for every time of equipment. Perform a regular inspection of the pump with the help of a qualified technician. It can help identify the problem and repair it before it becomes too serious of a problem.

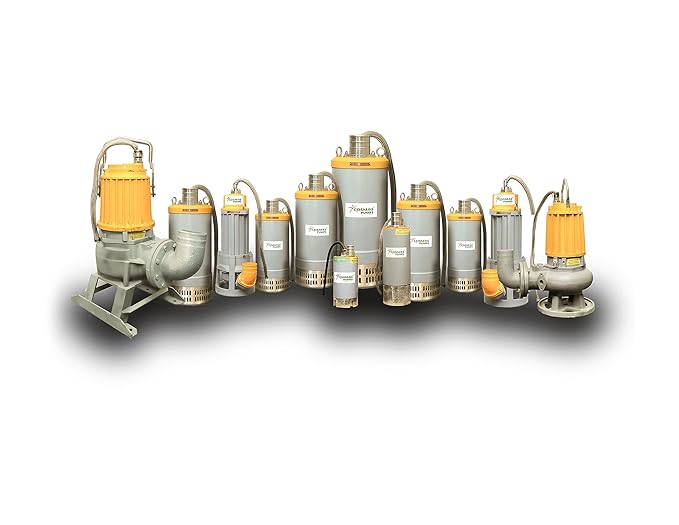

If you are in need of dewatering pump in Zambia then choose Cosmos Pumps. We provide optimum quality dewatering pumps in all of Zambia.