Water problems are a common problem in construction sites and can halt work. Stormwater, groundwater infiltration and nearby sources of water tend to accumulate in the excavations and weaken the soil. Ineffective water management slows down work and raises safety hazards for workers, machinery and ground support systems.

Good dewatering planning keeps the ground conditions stable and work progressing well. It also minimizes structural risks and expensive delays. This guide includes an overview of dewatering pump types and more.

What Type of Dewatering Pump Is Best for Construction Sites?

The best dewatering pump for your job is based on the conditions of the site. The decision is affected by numerous factors, including soil, water volume, trenching depth, power available and project duration. Temporary and permanent applications both demand quality equipment, but the latter also requires longevity.

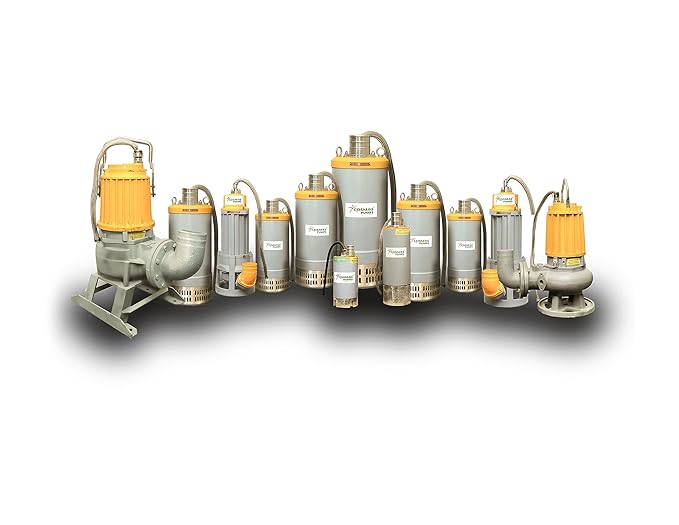

Submersible Dewatering Pumps

Submersible dewatering pumps work while underwater. They are located in a sump, pit or flooded excavation. These pumps are great for removing water from large areas and are easy to install. They are also small enough to fit in tight spaces such as basements and ditches. They operate quietly because they work underwater.

Diesel Dewatering Pumps

The internal combustion engine is the driving force of diesel dewatering pumps. They are used extensively at job sites without electricity or where power is inconsistent. These pumps provide a solid handling capability and can be used for large-scale open excavation in quarries. They’re able to cope with mud and debris well, but you will need to maintain your fuel and engine regularly.

Electric Dewatering Pumps

Electric construction dewatering pumps are a perfect match for urban and indoor construction sites. They are also low-noise and fume-free, which makes them safer for in-home use. Their recurring costs are less than those of diesel pumps, but they rely on a regular electricity supply. Such pumps are typically used for long-term work.

Portable Pumps for Temporary Works

Light in weight, portable pumps can be easily moved around the site. They are most appropriate for temporary water removal, such as after heavy rain or during shallow-depth construction projects. They are easy to install and uninstall, which means they can be a great solution for the short term.

How a Well-Point Dewatering System Works

A well-point dewatering system manages seepage at construction fields. It can draw down the water table in the vicinity of excavations. This results in dry and firm soil. The system employs several small wells linked by a pump. It operates constantly to prevent water from flowing into the workspace.

Main Components

The system has three key parts that work together.

- Well points: Small perforated pipes installed into the ground to collect groundwater.

- Header pipe: A horizontal pipe that connects all well points and carries water to the pump.

- Pump: Creates suction and discharges groundwater away from the site.

Step-By-Step Working Process

The system works in a simple sequence.

- Well points are installed around the excavation.

- They are connected to the header pipe.

- The pump creates suction.

- Groundwater flows into the well points.

- Water is discharged away from the site.

Typical Construction Use Cases

Well-point systems are used for:

- Shallow foundations

- Utility trenches

- Road and bridge works

- Sandy or silty soils

- High shallow groundwater areas

Diesel vs Electric Dewatering Pumps

Both diesel and electric pumps are commonly used on construction sites. The choice depends largely on site location, environmental restrictions, and operating duration.

| Basis | Diesel Dewatering Pumps | Electric Dewatering Pumps |

| Power source availability | Independent of grid supply | Requires stable electricity |

| Running costs and fuel dependency | Higher fuel and service costs | Lower operating cost |

| Noise and emission factors | Noisy with exhaust emissions | Quiet and emission-free |

| Suitability for remote and urban sites | Better for remote locations | Better for urban environments |

How to Calculate the Pump Capacity Required for a Building Site

Correct pump capacity ensures efficient dewatering. An undersized pump leads to flooding, while an oversized pump increases costs unnecessarily. Capacity calculation requires careful assessment of site conditions.

Estimating Water Inflow

Water inflow includes groundwater seepage, surface runoff, and rainfall. Soil permeability plays a major role in determining how quickly water enters the excavation. In uncertain conditions, trial pumping helps estimate actual inflow rates.

Head and Discharge Distance

Head refers to the vertical height the pump must lift water. Discharge distance affects friction losses in hoses and pipes. Longer discharge lines reduce efficiency, so both factors must be included when selecting pump capacity.

Solid Content Considerations

Site water at a construction site is often dirty enough to include sand, silt and junk. Pumps should be able to handle solids without blocking. When you get to higher solids content, you will need heavy-duty pumps suitable for abrasive conditions.

Common Capacity Ranges

A 5 HP pump is recommended for small pits and trenches. A 10 HP pump does a good job for an average depth excavation. Deep basements, large foundations and constant high inflows require heavy-duty pumps.

Problems Caused by Improper Dewatering and How to Fix Them

Mismanagement of dewatering can result in catastrophic construction problems. Most site delays and problems associated with water are avoidable with planning.

Water Accumulation and Site Delays

Standing water halts excavation, reinforcement, and concreting activities. Delays increase labour and equipment costs. Using adequately sized pumps and keeping backup units on standby helps prevent downtime.

Soil Instability and Foundation Risk

Wet soil loses strength and may collapse or settle. This poses a risk to the stability of the foundation and the safety of its long-term structure. Continuous dewatering and well-point systems prevent the soil from getting muddy and unstable.

Equipment Damage

The machinery, tools, and electrical systems are damaged by water exposure. Corrosion and short circuits are common risks. Proper pump placement and drainage channels protect valuable equipment.

Correct Pump Sizing and Placement

Incorrect pump sizing reduces efficiency and effectiveness. Poor placement results in uneven drying of the site. Pumps should be placed at the lowest points, based on a proper site assessment.

Dewatering Pump Cost in India

The cost of dewatering pumps varies based on type, capacity, and usage model. Understanding pricing factors helps plan project budgets more accurately.

Factors Affecting Price

Pump power rating, construction material, brand, and durability influence cost. Additional features like solids handling capability also increase the price.

Diesel vs Electric Pump Pricing

Initial and running fuel costs are generally higher for diesel pumps. Electric pumps have a lower operating cost but require reliable power, so they are best suited for large-scale, long-term urban projects.

Capacity and Material Impact

Higher capacity pumps cost more due to stronger motors and materials. Cast iron pumps last longer but are heavier and costlier. Lightweight pumps reduce upfront cost but may wear faster.

Rental vs Purchase Considerations

Renting pumps is economical for short-duration projects. Purchasing is more suitable for contractors with recurring dewatering needs. Rentals also reduce maintenance responsibility.

Which Pump Is Suitable for High-Groundwater Projects?

High groundwater levels create constant inflow pressure. Standard pumps may fail under such conditions, so specialized solutions are required.

Submersible Pumps for Continuous Operation

Submersible pumps handle continuous operation efficiently in flooded excavations. They are well-suited for deep pits and basements when monitored and maintained properly.

Well-Point Systems for Shallow Excavation

Well-point systems lower the groundwater across a wide area. They are ideal for shallow excavations and loose soils where water control is critical before digging.

Deep Well Pumps for Large Projects

Deep well pumps manage groundwater at greater depths. They are used in tunnels, large foundations, and infrastructure projects. These systems require professional design and installation.

Maintenance Steps for Dewatering Pumps

Regular maintenance ensures reliable pump performance and longer service life. Simple daily checks prevent major breakdowns.

Daily Inspection Checks

Operators should check the power or fuel supply, listen for abnormal noise, and monitor discharge flow. Visible leaks should be addressed immediately.

Cleaning and Clog Prevention

Strainers and inlets should be frequently cleaned. Pumps need to be rinsed out with clean water to prevent a sand build up, especially after heavy rains.

Hose, Seal, and Cable Inspection

Hoses should be inspected for leaks and cracks. Check seals and cables for damage or wear. Faulty parts should be replaced early.

Storage and Shutdown Practices

Pumps should be drained, cleaned and dried prior to storage. They should be covered and turned off in accordance with the manufacturer’s recommendations.

FAQs

What is a dewatering pump used for in construction?

A dewatering pump removes excess water from excavations and construction sites. It contributes to a safe and stable work environment.

Which dewatering pump is suitable for continuous operation?

Submersible water pumps are designed for continuous use. They work well underwater for extended periods.

How does a well-point dewatering system control groundwater?

It lowers the groundwater table using multiple small wells connected to a pump. Continuous suction prevents water from entering the excavation.

What factors decide dewatering pump capacity?

Water inflow rate, lift height, solid content, and site size are key factors. Project duration also affects capacity selection.

Is a diesel or electric dewatering pump better for construction sites?

Diesel pumps suit remote sites without power. Electric pumps are better for urban sites with reliable electricity.

Conclusion

Dewatering pumps serve as a significant aspect of construction safety and efficiency. The right pump depends on site conditions, depth of the water table and project life. Correct capacity estimation helps avoid flooding and delays. Both cost planning and proper maintenance contribute to budget control and more effective long-term performance. By selecting the right dewatering solution, you can safeguard foundations, equipment and employees, plus remain on track to complete your construction project on time.