Do you need to transfer a lot of water fast? If so, one of the most creative and economical fixes is to get a dewatering pump. The purpose of this kind of pump is to collect water and move it to safe locations. They are employed for drainage in underground constructions such wells, tunnels, basements, and commercial and residential buildings. Know about How Dewatering Pumps Work?

This pump has consistently shown to be effective, regardless of the size of the task! But how can you tell what will work best with so many options available today? Every aspect for a dewatering pump that meets your needs is covered in this blog post.

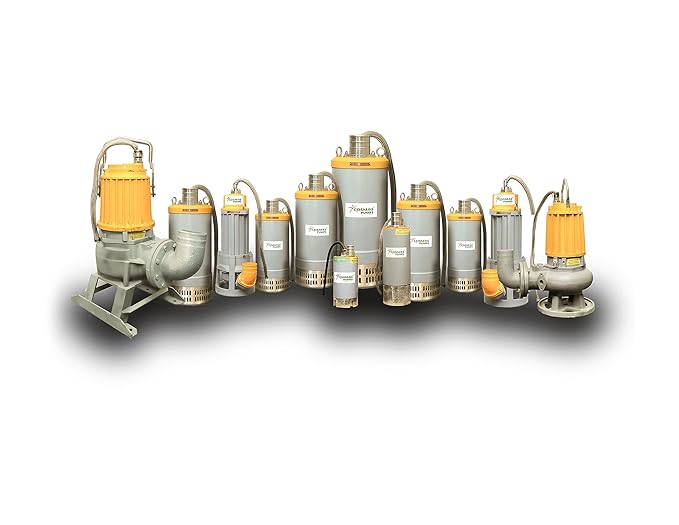

Pump for Dewatering

In places with an abundance of moisture, a dewatering pump is one kind of pump used to remove unwanted water. It is frequently utilized in mines, basements, flooded fields, and building sites. The groundwater buildup is removed by the pump using a vacuum, which directs the water into a drainage pipe or tank. In addition to filtering and reusing the drained water, dewatering pumps also help cut down on the expense of disposing of wastewater.

Fundamental Dewatering Pump Component

A dewatering pump in Nigeria is made up of multiple parts. Among the most important and useful parts of a dewatering pump are:

Pumps: The pump is the most important part of a dewatering pump. Small manual pumps for home or agricultural usage and big industrial pumps for heavy-duty applications are only two examples of the many sizes and materials available for pumps. They are made with impellers that swiftly transfer water through the system and out of the drainage-required area.

Pumps and valves work together to provide ideal flow control, pressure stability, and safety measures against flooding hazards. Depending on the needs of the application, many valve types—such as globe valves, swing check valves, and gate valves—can be used.

Lines of Discharge

Discharge lines move water into a reservoir or storage container and away from the area where it was being pushed out. By regulating the amount of fluid entering and leaving the system at any given moment and containing overflow potentials during times of high output, they also aid in maintaining pressure balance within the dewatering pumping system.

Panels of Control

Control panels link all of the parts so that they function seamlessly as a unit when activated by an external source (such a controller), which causes the parts to move concurrently when users have pre-programmed the desired outcomes.

These are the principal parts of a dewatering pump system; however, hoses, flow meters, moisture sensors, and other ancillary equipment can be required to guarantee proper functioning.

Building of the Dewatering Pump

Usually built with a centrifugal pump, a dewatering pump consists of an impeller, diffuser, shaft seal, motor unit, and volute. In order to flow water via the volute, the motor rotates the shaft, which in turn spins the impeller quickly. As a result, the volute develops a low-pressure area that attracts water from its surroundings. The diffuser then lets the liquid flow into a bigger area before it exits via the pump outlet, which helps to further lessen stress on the liquid being pumped out.

How Are Dewatering Pumps Operated?

A dewatering pump uses suction to drain water from a certain region. It sucks water up into the suction line and out of the discharge nozzle while producing negative pressure in the surrounding area. In general, certain filters let liquids pass through while trapping solids. This can be accomplished using a submersible dewatering pump in India or as a component of a larger mechanical system that includes valves, tanks, pumps, and filters.

Last Remarks

One useful instrument for draining water from flooded areas is a dewatering pump. Selecting the dewatering pump that best suits your needs is crucial because they come in a variety of sizes and designs.