Dewatering pumps are essential tools in construction, mining and various industrial applications. They help manage water levels, keeping sites dry and safe. However, like any other machines, proper maintenance is the key to Prolonging of Dewatering Pumps. Whether you are using a Dewatering Pump in Australia’s challenging mining environments or managing water in arid landscapes of Bahrain; these maintenance tips will help you get the most out of your equipment.

- Regular Inspection and Monitoring

Consistent inspection is the cornerstone of good maintenance. Your Dewatering Pump should be checked regularly for any signs of wear or malfunctioning. This includes checking the pump’s flow rate, pressure and noise levels. Early detection of problems can prevent larger issues from developing that may take time to fix and cost money to repair. In places like Australia where environmental conditions can be quite harsh, appropriate frequency of checks are vital so as to avoid sudden breakdowns.

- Pumps are kept free of debris

Dewatering pumps can become less efficient and wear out before their time due to dirt, debris and sediment blocking them. Therefore, it is important to keep the pump and its components clean. Doing regular removal of deposited materials from the pump casing, impellers and filters is essential. In some parts of Bahrain where accumulation of dust and sand happens frequently, frequent cleaning of the pump is important in order to avoid blocking as well as ensure a smooth running.

- Moving parts are lubricated

Proper lubrication of the pump’s moving parts is essential to reduce friction and wear. All bearings, seals and any other moving parts must be lubricated according to the manufacturer’s specifications. In regions like Australia where high temperatures make lubricants evaporate quickly, it is necessary to check and replenish lubrication levels for pumps.

- Monitor Pump Alignment

If a pump is not aligned properly, its components will wear down more quickly shortening its lifespan. To be on the safe side, check your Dewatering Pump’s alignment regularly and make necessary adjustments. Sometimes misalignment occurs due to poor installation and this is why it is very important to ensure that such pumps are installed correctly from the beginning hence in Bahrain which has shifting ground conditions one has to always check and correct the alignment so as to avoid damage.

- Use the Right Pump for the Job

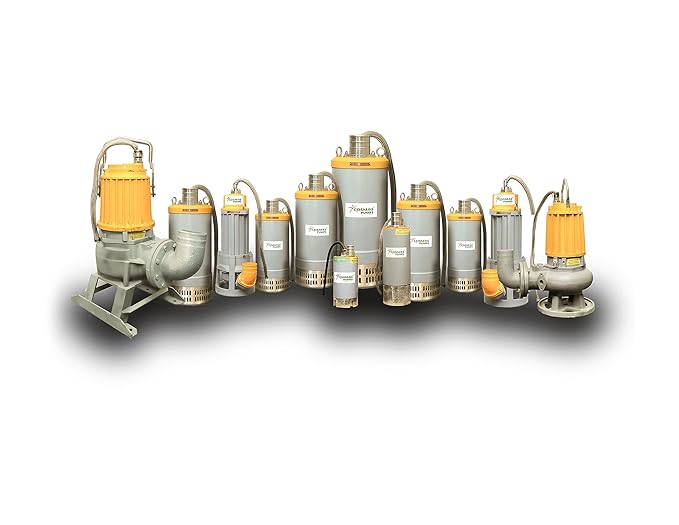

Choosing a suitable pump for your specific application is a must thing. A pump can easily get damaged when you overload it or use it under conditions which it was never meant for. If you are in Australia and you have heavy dewatering needs, make sure that you get yourself an appropriate kind of rough use pump that will be able to handle the workload at once without failing sometimes. People dealing with lighter applications here in Bahrain may choose smaller but more efficient types of dewatering pump in Bahrain instead.

- Proper Storage and Handling

You need to ensure the life of your dewatering pump even when it is not in use.Keep your pump in a clean and dry environment that will prevent rust and corrosion. For humid areas like Bahrain, desiccants and other methods of moisture control help protect the pump during storage. In Australia, which often experiences temperature extremes especially highs above 40°C or lows below 0°C, a temperature controlled environment can avoid damages associated with heat or cold.

- Regularly Replace Worn Parts

Whether you maintain it well or not, some parts of your pump will eventually require replacement. Maintain a record of maintenance activities and follow all manufacturer instructions on when to replace things like seals or rubbers (gasket) or even ball bearings. Preventing breakdowns by regularly replacing these parts extends their usability as much as possible thus making the device last longer.

Conclusion

These maintenance tips can help you prolong the life of your dewatering pump considerably thus making it perform efficiently and reducing down time as well. Regular maintenance is crucial in keeping dewatering equipment working properly whether one is using it in Australia or operating an equipment in Bahrain. Taking time to care for and maintain not only saves money over time but also makes sure that one’s dewatering operations continue to run smoothly in these environments regardless of their setbacks.