For the construction, mining, and disaster relief operations, Dewatering Pumps play a crucial role in managing water levels efficiently. The landscape of dewatering solutions has evolved rapidly, driven by innovations and solutions that enhance performance, efficiency, and sustainability.

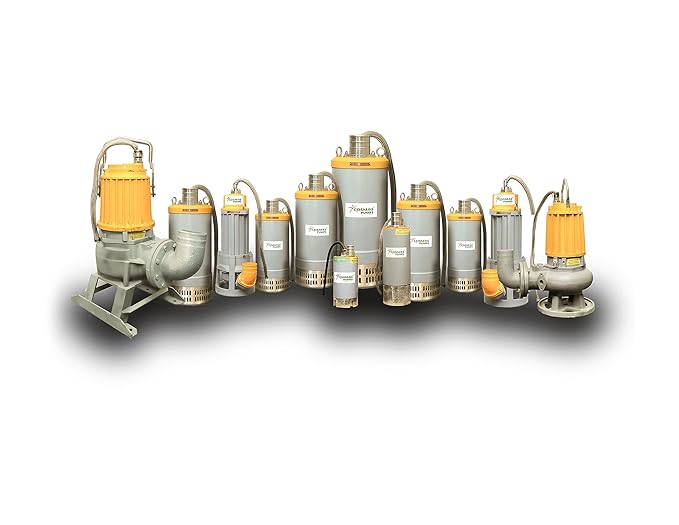

Advanced Dewatering Pump designs

Modern dewatering pumps rely on advanced materials and designs. Top suppliers also attempt to deliver the best Dewatering Pump Prices to improve durability and operational efficiency. With such reliable Dewatering pump suppliers, it is easy to ensure that you get solutions that have a better operational lifespan.

Solutions such as stainless steel and high-strength polymers are gaining traction. Such dewatering Pumps offer better value for money. These are also resistant to corrosion and wear and tear. It further reduces your selected dewatering Pump Price and minimises downtime.

Smart and innovative IoT technology

Modern Dewatering pump suppliers focus on integrating IoT technology into their dewatering systems. The resulting smart Dewatering Pumps (AutoPrime Pumps) can be equipped with the CosmoSmart kit to monitor aspects such as fuel consumption, service alerts, location tracking, and pump performance in real time.

Such solutions are vital for predictive maintenance, optimising operational efficiency and controlling the risks of unexpected breakdowns. Through such solutions, it is possible to save on the long-term Dewatering Pump Prices and achieve better operational performance.

Energy-efficient and sustainable solutions

Top manufacturers and Dewatering pump supplies are placing increasing importance on sustainability. The result is an efficient dewatering pump with IE 3 and IE4 levels. It helps regulate power consumption based on overall demand, energy savings, and other factors.

The use of eco-friendly materials and designs helps reduce the environmental impact of pump manufacturing and operations.

Compact and portable solutions

In response to the growing demand for mobility and flexibility in dewatering solutions, top manufacturers are focusing on developing compact and portable dewatering pumps. These can be easily transported or adapted to the desired environment. Such solutions are thus practical for various environments, as they enhance utility in construction sites and emergency management.

Integration with remote monitoring and control systems

Advancements in communication technology have enabled such solutions to integrate seamlessly into remote monitoring and control systems. Operators can easily monitor and manage the pump and its operations remotely.

The use of cloud-based platforms enables the provision of real-time insights, ensuring proactive adjustments are made to optimise efficiency and performance.

Frequently Asked Questions

- What is the dewatering pump?

A dewatering pump is a specialised pump designed to remove wastewater or unwanted water from construction sites, mines, tunnels, flood-affected areas, and other similar locations. It helps to pump out groundwater, rainwater and other stagnant water sources.

- What is the purpose of dewatering?

The process of removing UNWANTED water from a site, city, or surrounding is called Dewatering. It is crucial for civil engineering works, the mining sector, power plants, and other similar industries.

Through an ideal dewatering solution, it is possible to ensure that your selected work area remains safe and stable.

Other benefits of dewatering solutions are –

- It offers a safe and stable ground

The primary reason for choosing a dewatering pump is to create a safe and dry working environment. It is crucial for the construction and excavation process.

- Controls seepage

For sites with a high water table or those near water bodies, such solutions are crucial. These prevent water seepage into your foundation, trenches, pits, and other areas. Thus, it controls the risk of accident damage, equipment damage and construction delays.

Hence, for the construction of basements, tunnels or bridges, the solution helps to overcome flooding or instability.

- Improves soil stability and strength

Operating in a water-saturated soil is tough. It can easily become weak and unstable. It creates problems for civil engineering works and is unsuitable for supporting structures. It also improves the bearing capacity of the soil. It is crucial for foundation and road construction.

- Facilitates the construction projects

Dewatering solutions aid in excavation and reduce the amount of groundwater.

What is the difference between a water pump and a dewatering pump?

Feature Water pump Dewatering pump

Purpose: Moves clean or processed water Removes unwanted and dirty water

Design General use and is used irrigation or supply. Built for high solids and rugged conditions

Durability Standard material More robust and resistant to clogging. Suction Handling May struggle with air and water mix. Designed with debris, air and water mix.

- What is the working principle of a dewatering machine?

The working principle of the pump includes the following –

- Suction – The pump creates a vacuum that draws in water.

- Impeller – Helps to move the water up.

- Discharge – The water is pushed through a hose or outlet to the selected area.

These may vary depending on the type of pump. For example, centrifugal pumps use rotating impellers, while diaphragm pumps employ a reciprocating action for moving thick water. Submersible pumps are ideal for pushing water.

- What is the price of a dewatering pump?

The price range of these pumps is based on the capacity and brand. For example, industrial solutions with a price of 5+ HP are available upon request.