When considering the performance and efficiency of self-priming pumps and drainage pumps, proper maintenance should always be emphasized. The use of these pumps is not only common but vital in managing water especially in the construction and dewatering processes. Whether dewatering pumps for construction, a submersible dewatering pump or sludge pumps, the following maintenance tips will be effective in keeping your equipment in perfect state.

Self-Priming Pumps: Maintenance Tips

Maintenance done on a consistent basis minimizes down time and prevents breakdowns which are expensive. Mentioned below are some of the maintenance tips:

1. Inspect and Clean the Impeller

- Impellers are highly susceptible to dirt and can get clogged up which will reduce their efficiency.

- The impeller is usually subject to excessive wear and at times includes deposits that need to be removed to prevent any performance problems.

2. Monitor Seal and Gasket Integrity

- Check up the seals and gaskets and their positions to make sure that there are no leakages.

- If the pump has a lot of air leaks, seal the leaks and change the seals with new ones, or any difficult priming problems will develop.

3. Check for Air Leaks

- Self priming mechanisms will be defeated due to air leaks.

- Pump casing, suction line and air pipe should be checked thoroughly for cracks, loose connections or any signs of air leak.

4. Maintain the Strainer

- Some self-priming pumps employ a strainer that keeps out unwanted items from the fluid.

- Always ensure that the strainer is cleaned periodically as a measure of preventing cloggings.

5. Lubricate Bearings

- Bearings when lubricated well and at the right time, will make the pump system effective.

- Adhere to the manufacturer’s recommendations on relubrication timing and use the correct oils.

Drainage Pumps: Maintenance Tips

Drainage pumps – especially the submersible types – are commonly used to perform jetting and pumping operations in activities such as management of construction sites and flood control. Maintenance practices in respect of the equipment can help to ensure that they can work effectively even in extreme environmental conditions.

1. Clean the Pump After Use

- Drainage pumps efficiently remove water, but often removal denotes a process involving removal of water with debris.

- A transfer pump should therefore have its casing, impeller and even the inlet cleaned to avoid any clogs.

2. Inspect Power Cables and Connections

- Especially when working underwater, always check for any damage that may be found to the cables of a submersible pump.

- It is also important to check that the connections are tight to prevent any disconnection that may cause electrical problems.

3. Monitor the Float Switch

- This has the purpose of controlling the functioning of the pump.

- Always do a test run on the sensor to see whether the pump pushes in or out the water within healthy time brackets.

4. Prevent Overheating

- Do not run the pump without water in it because this will cause overheating of the machine and later damage it.

- Allow some cooling and do not push the pump beyond the designed capacity.

5. Check for Wear on Seals and Bearings

- Water is typically used as the medium to seal internal parts in dewatering pump submersible.

- Readjusting with new bearings and seals helps in preventing water entries inside the dynamo.

General Maintenance Tips for Dewatering and Sludge Pumps

Irrespective if you are employing construction dewatering pumps, sludge pumps, or any other heavy duty equipment these measures are applicable.

1. Conduct Regular Inspections

- Put in place periods in which rejoinders will be offered to check for wear and tear, leakages, or blockages in pipes.

- Take special care to those pump parts which come into contact with abrasive or corrosive media.

2. Use Clean Power Sources

- Provide sufficient and uninterrupted supply of electric power to the powering electric pumps.

- Where pumping systems are employed make sure proper maintenance and operation of the engines and fuel systems is carried out.

3. Store Pumps Correctly

- Stop your pumping activity and properly pack the pumping equipment, it should be done in the work space that is clean and devoid of moisture.

- Remove any left-over water to avoid frost and rust formation.

4. Follow Manufacturer Guidelines

- Obey the user’s guide with regard to the timings of maintenance schedules and the replacement of the necessary parts.

- Always use genuine parts like those in the equipment’s box for all the replacement purposes.

5. Test Pumps Regularly

- Pumps need testing at regular intervals to make sure they are available for use when the need arises.

- Test the pump for a few seconds and analyze for any strange sounds or vibrations.

FAQ

Why Maintenance Matters?

- Increases the lifespan of your dewatering pumps, sludge pump and other equipment in the facility.

- Provides assurance when it comes to critical practices such as Dewatering in construction sites or sewage transportation using sludge pumps.

- Cost effective in avoiding unanticipated system failures and costly repairs.

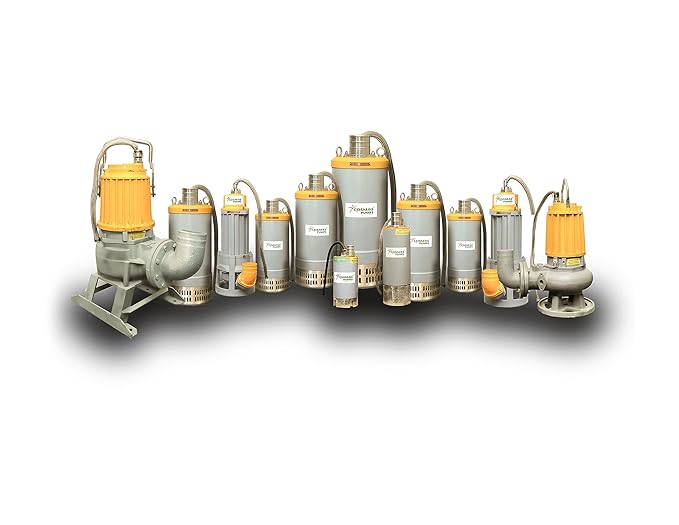

At Cosmos Pumps, we offer a range of durable and effective dewatering pumps, submersible pumps and sludge pumps. For more information or to get an effective solution for your construction or industrial problem, give us a Call today!