Industries that handle wastewater, leftover materials from mining operations, construction debris, or manufacturing by-products often face a challenge in regard to transporting large volumes of thick and viscous materials. This is where sludge and slurry pumps play a critical role.

By learning about sludge and slurry pumps and how each type works best, engineers and operators can pick the right pump for their needs, which will make their work more reliable and efficient.

Working Principle Of A Sludge Pump

A sludge pump is a device that functions by dragging the thick and semi-solid waste, which is capable of operating at a high content of solids without being clogged or excessively worn. The following are some of the fundamental principles:

Basic Design and Construction

The sludge pump is developed to transfer semi-solid wastes with a high content of solids that are combined with liquid. The pump is normally characterized by a heavy-duty casing, a powerful impeller, and extensive internal clearances.

The pump bodies are made of cast iron or hardened alloys, depending on the chemical nature and abrasiveness of the sludge. Seals and bearings are strengthened to withstand heavy loads and contaminated liquids.

How Sludge Is Moved Through The Pump

Sludge pumps are either centrifugal or positive displacement. The centrifugal force is generated in the device with the help of the rotating impeller, which pulls the sludge to the centre and forces it out through the discharge.

The broad passages between the flows minimise the chances of blockage by thick or irregular solids. This method is especially beneficial in extremely thick or viscous sludge, in which the consistency of flow is of paramount importance.

Solid Handling Capability

The sludge pumps can be used in dealing with material of high solids content that can be even more than 20-30% by weight. They are capable of passing huge particles, fibrous waste and settled solids without any major performance degradation. This makes them appropriate for applications such as sewage treatment, industrial waste transfer and thick sediment removal.

Typical Operating Conditions

The sludge pumps typically have low to moderate flow rates and a relatively low head in comparison to the slurry pumps. They are usually used in situations where the substance is slow, sticky or inclined to settle. The choice of pumps and operating limits depends on temperature, chemical composition and size of solids.

Which Slurry Pump Is Best For Thick Waste Material?

The choice of the appropriate slurry pump to be used in the thick waste material is dependent on the concentration of solids in the flow and the abrasiveness of the particles. This ensures that the solids can be transferred to the waste material efficiently, with a minimal amount of wear and long-term service.

Nature Of Thick and Abrasive Waste

Slurry pumps are also applied to mixtures of solids and liquids, especially where the solids are hard, abrasive and suspended uniformly. Mining, mineral processing, and dredging typically have thick wastes that may present sand, ore particles, or tailings that rapidly wear out regular pumps.

The best slurry pump to use with thick waste depends on the size of the particles, concentration and hardness.

Pump Construction and Materials

Slurry pumps are made using abrasion-resistant materials of high-chrome alloys, rubber-based lining or hardened steel. The most important wear parts are the impeller and casing, which are meant to be replaced.

Metal-lined slurry pumps are used where a high level of abrasiveness is required. Pumps that are of rubber are more suited to fine particles and corrosive slurries where flexibility and chemical resistance are essential.

Flow Characteristics

The slurry pumps are centrifugal types and have higher flow rates and heads compared to the sludge pumps. They are streamlined to ensure the solids are held in suspension, and the solids do not settle along the pipeline. They need to be sized properly so as to retain the necessary velocity and prevent blockages or excessive wear.

Industrial and Mining Use Cases

The slurry pumps are widely used in the mining industry in order to carry the ore slurries, tailings, and concentrates. They are also utilized in power plants that deal with ash slurry, mineral processing plants, and dredging operations. Durability and high performance in abrasive environments are some of the factors in these environments.

Difference Between Slurry and Sludge Pumps

The Slurry and sludge pumps are created to handle fluid that is filled with solids, though they vary in the material consistency, pump design, wear resistance, and are commonly put into use in industrial and wastewater conditions. The major differences are the following:

Material Consistency Handled

The main distinction is in the nature of the material processed. Sludge pumps are made to handle thick, semi-solid, and mostly sticky wastes, which have a high rate of solids. Slurry pumps are used in handling liquid-solid mixtures where the solids are abrasive but suspended in the liquid.

Pump Design Differences

Sludge pumps are centered on non-clogging and passing large or irregular solids. A recessed or open impeller is often used. Slurry pumps are designed to handle abrasive content with specifically designed impellers and volutes, so as to achieve hydraulic efficiency.

Wear Resistance and Maintenance

Abrasive particles damage slurry pumps heavily. Therefore, wear resistance is a key design consideration. The parts are suited to be replaced easily. Sludge pumps have more problems with clogging and seal contamination, so alternative maintenance approaches are needed to overcome the blockages and preserve bearings.

Application Environments

Sludge pumps are widespread in wastewater facilities, industrial effluent work and sewage systems. The slurry pumps are also more common in mining, mineral processing, power generation, and dredging, where abrasives are the dominant materials.

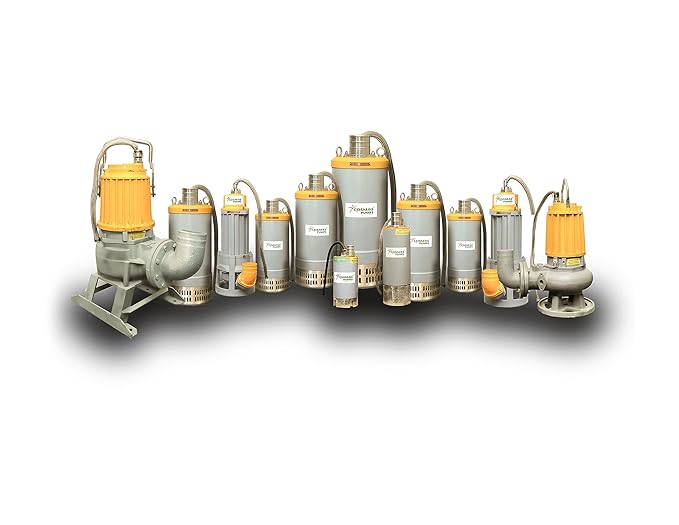

Why Submersible Mud Pumps Are Used At Construction Sites

The submersible mud pumps are mostly common in construction sites as they can easily manage the solids mixed with muddy water and even offer good dewatering, although in limited or temporary workplaces.

Handling Muddy Water With Solids

Construction sites usually produce muddy water with sand, soil and debris. The design of submersible mud pumps allows this kind of material to be processed without a clog or high rate of wear. The capability of operation when fully submerged means that they can attract water even when there are pits, trenches or flooded zones.

Installation Advantages

Few efforts are needed in the installation of submersible mud pumps. It is used underwater and therefore does not require priming or any complicated suction piping. This ease of use makes them suitable for short-term or interchangeable site conditions.

Mobility and Space Considerations

Construction sites are usually congested and dynamic. Submersible pumps are small, portable, and can be moved anywhere where necessary. They can be easily used in limited areas where surface-mounted pumps would have been infeasible.

Continuous Operation Requirements

Dewatering of many construction activities is necessary in order to keep the working conditions safe and dry. Submersible mud pumps are made to be constantly active and have the ability to withstand the changes in solids content without frequent shutdowns.

FAQs

1. What is a sludge pump?

The sludge pump has been made to transfer solid waste with a high percentage of solids. It has been specifically manufactured with an extended range of features, allowing it to work effectively with irregular or fibrous elements.

2. What is a slurry pump used for?

Slurry pumps are used for transferring liquids with hard particles such as ore, ash, etc. This type of pump is usually found in various mining and processing industries.

3. How do slurry pumps handle abrasive material?

Slurry pumps use materials that resist wear, such as high-chrome alloys or rubber linings. This is because these types of pumps are designed to maintain the suspension of solid particles in liquid form.

4. Can slurry pumps be used for sludge applications?

In some cases, yes, but slurry pumps are less effective with very thick or sticky sludge that tends to settle or clog.

5. Where are submersible mud pumps commonly used?

These are often used at construction sites, tunnelling projects, and dewatering operations where muddy water with solids needs to be removed quickly.

Conclusion

Sludge pumps are designed primarily for thick, semi-solid, and viscous wastes. On the other hand, slurry pumps provide a higher volume rate of an abrasive liquid or a fluid with a heavy load of solid particles in it. Selecting pumps that match the material characteristics is vital for dependable pumping operation.

Proper selection not only improves performance but also reduces maintenance, energy consumption, and overall operating costs.