What is Dewatering?

The process of removing UNWANTED water from a site, city, or surrounding is called Dewatering.

What is a Dewatering Pump?

Anywhere water needs to be removed, a centrifugal pump is utilized as a dewatering pump. When removing undesired water from buildings, tunnels, mines, and construction sites, municipal sites, General infra, Power plant and Defence areas, you can use the pump. The kind of water as per viscosity you plan to pump determines the kind of dewatering pump that should be employed.

Uses and Industries

The following are a few typical uses for dewatering:

- Mining: In mining operations, our diesel dewatering pumps are heavily utilized, mostly for the purpose of removing water from trenches and low-lying areas and releasing it far from areas of active activity.

- Construction sites: During the foundation casting stages of construction, dewatering becomes essential. Building sites that are deeper always require larger, more sophisticated pumps.

- Tunneling: Since tunnels usually include water, controlling it is crucial to any major tunnel construction project. A variety of factors influence the choosing of pump. The most fundamental of these are the required head and flow rate.

- Power Plant: Water diversion is a challenging process without pumps. Because of this, most hydro project development involves pumping water and creating space so that DAM can be built.

- General Infra: Since dewatering pumps can manage varying water depths and flow rates, they are flexible solutions for a variety of infrastructure applications. Dewatering pump in UAE used in general infrastructure projects are constructed with durable materials and robust motors.

- Urban Works Department: Dewatering pumps are essential instruments for managing water levels at building sites, basements, and other urban infrastructure projects. The Urban Works Department uses them. Our pumps efficiently drain excess water, keeping the space suitable for work.

- Municipal: Municipalities require ecologically friendly, trustworthy, and energy-efficient equipment to appropriately dispose of wastewater. Cosmos Pumps offers wastewater management and pumping services to remove excess water that accumulates in urban areas.

- Defence: Its main applications are in the drainage of flooded areas, the preservation of dry conditions for the defense supply and equipment storage, and the ease with which defensive installations, airstrips, and highways can be built.

Types of Dewatering Pumps

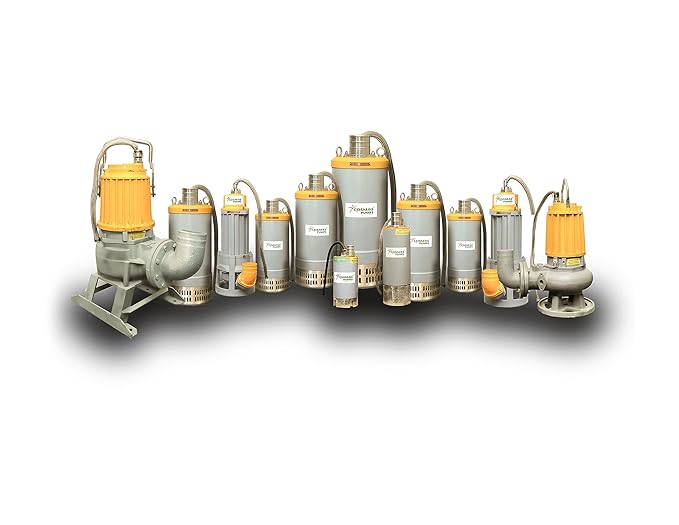

Every kind of pump, from Portable Submersible Pumps to Self Priming pump, has a specific function. Let’s examine these various pump types in more detail and see how they might be used to aid with dewatering.

Submersible Dewatering Pumps

Water is removed from the region using submersible dewatering pumps, which are intended for installation in a wet well or sump. These kinds of pumps are frequently used in places like building sites, Hydro Power plants and mines that need drainage. Submersible dewatering pumps can be purchased with electric drive, based on the intended use. These are of the following types:

- Drainage Pumps

Drainage pumps are made to take out undesired liquids from a variety of places, including tanks, crawl spaces, and basements. Depending on your demands, these pumps are available in electric-powered variants. The primary purpose of drainage pumps is to remove undesired water that build up over time as a result of flooding or other issues like damaged pipes.

- Sewage Pumps

Wastewater from residences, businesses, restaurants, factories, etc. is pumped out using sewage pumps into a main sewer line so that it can be adequately treated before being released back into the natural world. Depending on your needs, sewage pumps are available in electric powered types.

- Sludge Pumps

Sludge pumps are made to move sludge or slurry via pipes or hoses from one location to another. This is accomplished by moving liquid waste materials along with heavier particles like mud lumps and sand granules utilizing the centrifugal force produced by an impeller inside the pump body itself. It is combined with certain other solid components, such as chunks and grains, which makes this kind of pumping procedure extremely difficult to use but efficient in eliminating a variety of particles mixed with liquid waste products!

- Non-clog pump

Cosmos Pumps sells submersible sludge pumps in the CNC series. The CNC Series has many benefits, such as improved cable sealing, a more lightweight and compact design, improved resistance to abrasion, and genuine non-clogging.

- Slurry pump

Slurry pumps are a powerful, heavy-duty variation of centrifugal pumps that can handle demanding, abrasive tasks. The phrase “slurry pump” refers to a variety of powerful centrifugal pumps that are used to move solids from one point to another.

- Self Priming Pumps

Self-priming pumps are designed to handle water containing air or gas. These pumps can automatically evacuate air from the suction line, making them ideal for applications where the suction line may contain a mix of liquid and air. These are of the following types:

- Motor coupled

A motor-coupled self-priming pump integrates the pump with an electric motor, ensuring efficient power transfer and compact design.

- Diesel engine driven pump

Plumbing, sewage, and mining are among the industries where work is frequently done in isolated areas without access to electricity. Auto-priming pumps powered by diesel engines offer a flexible and dependable option under these demanding operating circumstances.

Advantage

By keeping a site dry and functional, a dewatering pump in South Africa can save downtime and boost output. Better working conditions: Removing extra water from a site might also make it easier to work there overall. It can contribute to lowering heat and humidity, improving worker comfort.

FAQs

What is a dewatering pump?

A dewatering pump is a type of specialist pump used to evacuate water from regions that are prone to flooding, such as municipal sites, tunnels, mines, and construction sites. These pumps are necessary to keep the environment dry and stop water damage to machinery and infrastructure so that daily operations are continue in full swing.

What sets a submersible dewatering pump apart from other kinds of pumps?

Because a submersible dewatering pump is made to function underwater, it can pump water from tight or deep places more effectively. These pumps are frequently utilized in situations where accessibility concerns or limited space make regular dewatering pumps inappropriate.

Which characteristics make submersible dewatering pumps unique?

Submersible dewatering pumps come with characteristics that guarantee dependable and effective performance even in harsh conditions. High-performance impellers for optimal pumping efficiency, integrated thermal protection to prevent overheating, robust design to withstand corrosion and abrasion, and automatic float switches for pump control in dewatering tanks or sumps are a few examples of these qualities.

Which aspects need to be taken into account when choosing a dewatering pump?

The flow rate and head requirements, the kind of fluid being pumped (water, slurry, or water with abrasive material), the operating conditions (such as the depth of submersion and ambient temperature), and any site-specific restrictions or challenges should all be taken into account when choosing a dewatering pump. Furthermore, consideration must be given to elements like pump dependability, ease of upkeep, and compatibility with current infrastructure in order to guarantee peak performance and longevity.