In industrial applications, efficiency and reliability are paramount. Efficiency and reliability are the determining factors that show whether a company gains or loses revenue. Thus, choosing the right pumping equipment is extremely important. Suppose you work in construction, mining or even the chemical industry, In that case, you will be working in an aggressive, high-performance environment, and a quality slurry pump makes all the difference.

A slurry pump keeps the process moving, reduces downtime, and therefore increases productivity. With so many varieties of slurry pumps on the market, how do you find the right slurry pump?

This blog will talk about the most crucial steps to choose the perfect slurry pump for your specific needs in your industry, to ensure things continue to run effectively.

Evaluating Your Industry’s Needs

When selecting the best slurry pump, begin by evaluating your industry’s particular needs. All industries are different from one another: in mining, the pumps should withstand extremely abrasive slurries such as coal or ore suspensions; in sewage treatment, they deal with thick sludges which are organic; and in chemical processing, they should resist corrosion from acidic or alkaline solutions.

Start with a thorough analysis of the properties of the slurry. What is the particle size and concentration? Are solids abrasive and rough, such as silica, or smooth, such as clay? Slurry viscosity and specific gravity will determine pump power needs.

Selecting the Right Pump Material

Next, consider what the pump is made of, since this will also impact durability and lifespan. Slurry pumps are typically made from high-chrome alloys, rubber-lined casings, or expensive materials such as duplex stainless steel. If your process involves acid slurries, use pumps with elastomer linings so that they do not wear out.

With very abrasive uses, metal impellers are more resilient. If there’s a mismatch here, there is a possibility for frequent replacement and high maintenance costs. Discuss with your pump experts to cross-check the material with your slurry’s pH levels, temperature, and erosive nature. Getting it right could extend pump life by years.

Establishing Flow Rate and Head Demand

Flow rate and head demand are another key pair in the decision. The flow rate, expressed in gallons per minute (GPM) or cubic meters per hour (m³/h), sets the volume of slurry that a pump can transport. Underestimation creates bottlenecks, and overestimation wastes energy. Head, or the height to which the pump can lift the slurry, must be frictionless along the pipes. Use the manufacturer-supplied curves to graph performance. For example, in dredging, you might require a slurry pump that would provide high flow to clean riverbeds effectively. In contrast, a heavy-duty industrial water pump used in a factory facility demands even pressure for uninterrupted processing.

Efficiency and Energy Conservation

Efficiency and power usage cannot be avoided in the current environmentally concerned scenarios. New slurry pumps incorporate advanced hydraulics and variable speed motors to achieve low power consumption, reducing operating costs as well as environmental impact. Consider using high-efficiency rating pumps, especially if your operation is continuous 24/7.

Think about the total cost of ownership (TCO), comprised of the initial cost of purchase, installation, energy costs, and maintenance. A cheaper pump can be tempting, but if it needs to be constantly maintained, it will drain your bank account. Areas like construction, where mobility is critical, might need submersible water drainage pumps to be installed and maintained on the job site.

Exploring Slurry Pump Types

Slurry pump types vary widely, so knowledge about the options is required. The most prevalent by far are centrifugal pumps, which utilise rotational energy to pump slurries at high velocities. Positive displacement pumps, such as piston or peristaltic, prefer pumping thick, shear-sensitive slurries in pharmaceutical uses or food processing.

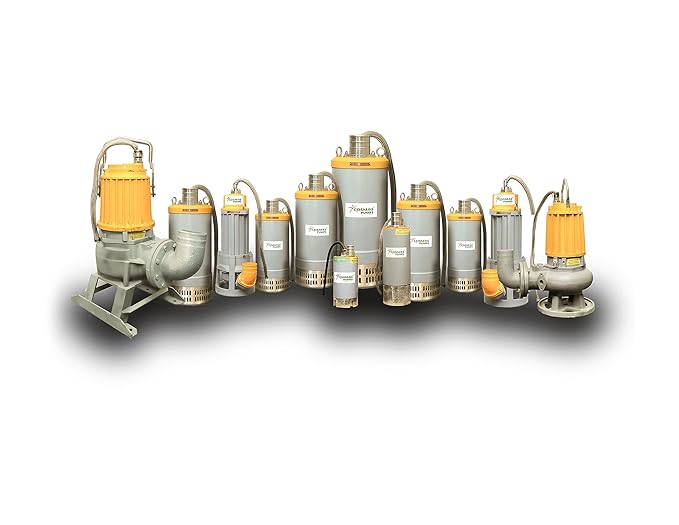

Submersible pumps, which can also be used as water drainage pumps, are appropriate for applications where the pump is placed in sumps or pits, providing reliability in flood areas. Heavy-duty applications, like deep mineshafts, need vertical turbine pumps.

Safety and Compliance

Safety features are also essential. Pumps that handle toxic slurries require seals to avoid leakage, explosion-proof motors where there is a chance of explosions and auto-shut-offs. Adherence to industry standards, e.g., ISO certification or API certification, ensures consistency and minimizes liability exposure.

Conclusion

In brief, the choice of the finest slurry pump is an inclusive process. By doing so, you will improve working efficiency, reduce costs, and prevent costly disturbances. Whether replacing a heavy-duty water industrial pump or the new installation of a water drainage pump system, the reward comes with a more durable industrial configuration.

When it comes to premium solutions tailored to suit you, Cosmos Pumps should be on your list. Integrating innovative designs and superior durability, Cosmos Pumps is able to provide trustworthy slurry pumps that are able to withstand the most challenging conditions. Get in touch with us and bring your operations to a whole new level!