We take pride in offering our advanced auto prime dewatering pump solutions that combine efficiency, reliability, and ease of use. As leading Auto prime pump manufacturers, we focus on designing pumps that operate flawlessly in challenging conditions, from high suction lifts to thick sludge removal. Our range of diesel dewatering pumps ensures that even locations without electricity have access to powerful, uninterrupted pumping performance. We understand that industries like mining, construction, and municipal water management require dependable equipment, which is why our pumps are engineered for durability, minimal maintenance, and long service life.

Our clients enjoy the quick start, constant flow and efficient solids handling, turning every project to a more convenient and cost-effective one with the selection of our AutoPrime pumps. We integrate our innovative technology with an effective design at Cosmos Pumps, so that our range of auto prime dewatering pumps can meet both standard and specialized needs.

The remote use, emergency response in management of floodwater and surface dewatering on a large scale are some of the applications where our diesel dewatering pumps are most desired. Being trusted manufacturers of auto prime pump, we are determined to be innovative, high performing at what we do and provide reliable solutions that can be relied upon by professionals working in various industries in the coming and future years.

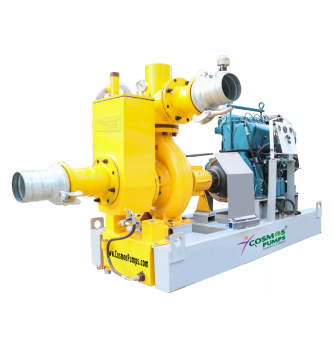

Cosmos Autoprime Surface Pumps Features and Benefits

We design our Cosmos self-priming pumps/AutoPrime Surface pumps to be reliable, efficient and durable. These pumps provide automatic priming and are ideal in the field of mining, construction, municipal and flood water. They suit both temporary and permanent installations and provide a steady flow even in difficult environments.

Cosmos Autoprime Surface Pump Advantages

- Automatic 100% dry priming: This ensures rapid start-up and continuous operation.

- High suction lift: Effective pumping to 8.5 meters.

- Long-lasting construction: Constructed to perform in harsh conditions over time.

- Flexible applications: It can be used in mining, construction, municipal works, and floodwater management.

- Diesel dewatering pumps on offer: These are suitable when operating without a grid and in remote locations.

Options

- Pump on small trolley

- Pump in silence canopy on trolley

- Stainless steel pump

- Pump on heavy trolley

- Pump on skid with crash frame

- Pump in silence canopy on skid

- Pump with diaphragm priming

- Electric pump on skid

Cosmos Autoprime Surface Pump Features

- Combination vacuum pump and priming tank: Provides a smooth auto-prime dewatering pump function.

- Optimised impeller design: Optimised impeller design:

- Maintenance: Easy to maintain, minimises downtimes, and maintains smooth operations.

- Consistent pumping operation: Can be used in a wide variety of applications and site conditions.

- Diesel dewatering pumps: Make sure you operate strongly even in remote areas.

Countries We Supply

- UAE: Supporting construction, municipal, and industrial projects.

- Saudi Arabia: Providing pumps for construction, municipal, and industrial projects, floodwater management.

- India: Extensive use in mining, industrial, construction, infrastructureand municipal dewatering.

- Qatar and Kuwait: Reliable AutoPrime pumps for surface dewatering and emergency water control.

- Bahrain and Nigeria: Diesel dewatering pumps for remote and high-demand dewatering and mining applications.